Nevertheless, while machine shops of all sizes continuously invest in advanced high-tech and networking equipment, they must also recognize and deal with the various cybersecurity threats that come along with the latest tech. Nowadays, no type of manufacturing industry is immune from cyberattacks. Hacker groups are using more advanced methods and techniques to access valuable company data and wreak havoc, so you need to know how to safeguard your machine shop against potential cybersecurity threats. Here are three frequent cybersecurity vulnerabilities that deserve attention and you need to know about.

#1. Unsecured CNC Machining Systems

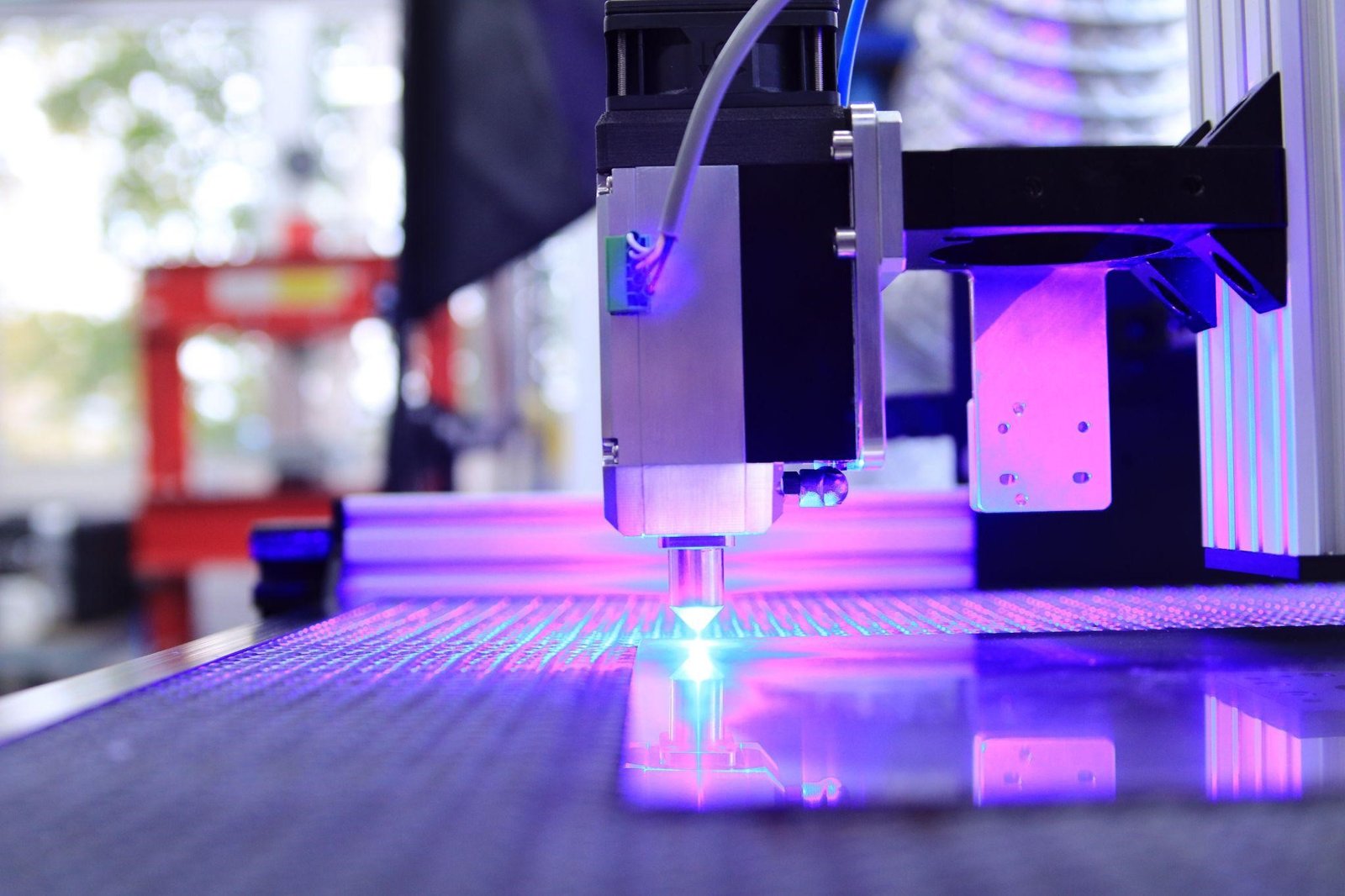

Connected CNC machining systems permit machine shop operators to fully automate their production process, irrespective of whether we speak about a CNC milling operation where the workpiece is rotated along axes and cutting tools are utilized to chip away pieces of the workpiece or a basic CNC-powered drill. While machine shops have these machinery sets connected to maintain steady workflows and automate operations, a lack of security for any of these tools could be disastrous for your business. For one, hackers could cause significant damage within the CNC system if they gain access to your network and begin digging through the pieces of information on your unsecured CNC system. For instance, they could manipulate the programming of your machinery to make it manufacture defective parts. Afterward, suppose the quality control department doesn’t notice the problem in time. In that case, these parts could end up on the market and create great danger for the companies or people using them, putting you and your machining shop in an unwanted position. Furthermore, cruel hacker groups can even infiltrate your CNC machining system to gain a competitive advantage over a rival of yours by stealing proprietary, confidential information about your manufacturing processes, something that you probably want to avoid at all costs.

To address this cybersecurity concern, you should lock down your CNC machining systems by installing authentication tools that deny or grant access to the company network based on user privileges and robust firewalls. In addition, you should always keep your software and systems updated because both become more vulnerable to attacks if they are outdated.

#2. Using Non-Encrypted Passwords

In case your machining shop utilizes the same password for various logins, or the different passwords you use are easy to guess (such as “password123” or “yourcompanyname123”) the likelihood that a hacker will gain access and do tremendous damage to your shop increases dramatically. Nevertheless, recent research showed that the primary issue for manufacturers and machine shops is not that their passwords are easy to guess but the lack of encryption. Recent research by CyberX looked over the primary issues faced by businesses that depend on the Industrial Internet of Things and control systems. The study showcased that the connected machinery and equipment used plain-text passcodes 69% of the time, meaning that only 31% of all manufacturing companies used encryption with their passwords. Remember that modern-day hackers usually perform reconnaissance to acknowledge which machines or networks would be the easiest to infiltrate. Afterward, they use this information to plan how and when to attack the manufacturing company. To avoid this potential issue, ensure that you use the latest tools to encrypt your passwords so that even if someone gains access, they won’t automatically have your protected data.

#3. Observe Your Shop’s Networks For Potential Data Smuggling

Last but definitely not least, did you know that data smuggling is one of the most frequent methods cybercriminals use to perform data exfiltration against manufacturing companies and machining shops?

By definition, data smuggling occurs when an external hacker utilizes an internal host device to access confidential data from at least one of your in-house servers and transfers the data to an external location. To safeguard your machining shop against this form of cyberattack, you need to monitor your networks continually and double-check for anything that seems suspicious or odd. If you happen to stumble upon something that looks odd, make sure to contact your IT specialist and let them investigate and dig deeper so you can recognize and identify the threat.

Final Words

The push toward the Industrial Internet of Things and Industry 4.0 has brought interconnectivity to industrial CNC machines, enabling machines and factories to mass-produce complicated products with great speed and precision. However, in doing so, the revolution has helped expose these CNC machining setups to the new potential threats mentioned above, something that needs to be considered and addressed intensely by machine shop owners if they want to stay operational and ahead of the competition.